Search

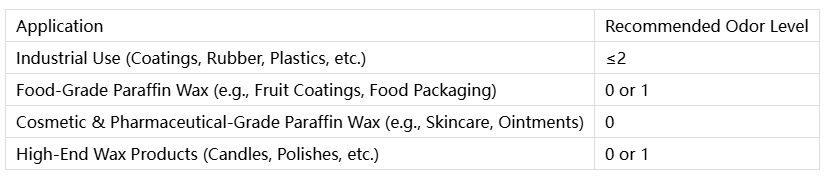

In the paraffin wax application industry, many customers prefer high-purity wax with no or minimal odor, especially for food-grade, pharmaceutical-grade, and cosmetic-grade products. However, even after hydrotreatment, some paraffin wax may still have a noticeable odor. Where do these odors come from, and how can product quality be further optimized?

Although hydrotreatment significantly reduces impurities, the following factors may still contribute to residual odors in paraffin wax:

Inadequate hydrogenation temperature or pressure, leading to incomplete removal of organic impurities.

Aging of hydrogenation catalysts, resulting in reduced desulfurization, denitrification, and deoxygenation efficiency.

Insufficient hydrogen purity, which may introduce trace odor compounds.

Feedstock containing aromatic hydrocarbons, sulfur compounds, or organic acids that are difficult to remove completely, even after hydrotreatment.

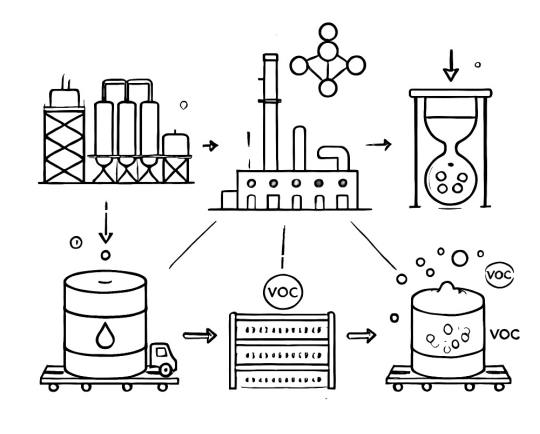

Oxidation reactions occurring during storage or transportation, leading to the formation of aldehydes, ketones, and carboxylic acids with noticeable odors.

Incomplete bleaching earth refining or activated carbon adsorption, failing to remove trace odor compounds effectively.

Residual odor-bearing substances in storage tanks and pipelines contaminating the final wax product.

Absorption of volatile organic compounds (VOCs) during transportation, increasing odor levels.

If the hydrotreated paraffin wax still exhibits a noticeable odor, the following optimization strategies can be implemented:

Increase hydrogenation temperature and pressure to ensure deep desulfurization, denitrification, and deoxygenation.

Replace aging catalysts with high-activity catalysts.

Utilize bleaching earth refining or activated carbon adsorption to remove residual odor compounds.

Ensure storage tanks and pipelines are thoroughly cleaned to prevent secondary contamination.

Minimize exposure to air to reduce oxidation.

For food, cosmetic, or pharmaceutical-grade paraffin wax, a combination of bleaching earth refining, activated carbon adsorption, and vacuum degassing is recommended to further reduce odor and enhance purity.

If you require stricter odor control for paraffin wax, feel free tocontact us. We offer customized optimization solutions tailored to your needs!