Search

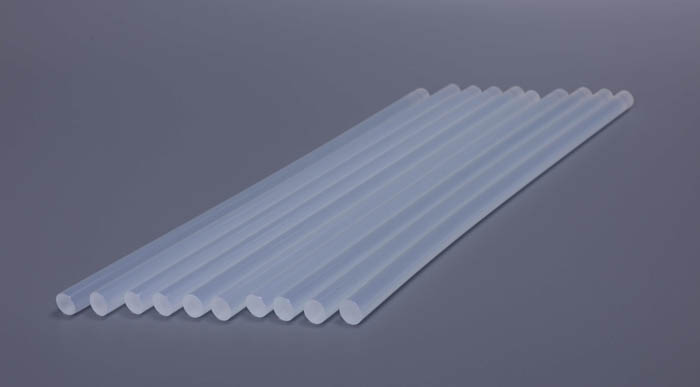

In recent years, with continuous technological advancements, the molecular structure optimization of Fischer-Tropsch (F-T) wax has achieved remarkable breakthroughs across various sectors, particularly enhancing performance and expanding applications in the adhesives, coatings, and plastics industries. F-T wax, a hydrocarbon compound synthesized from syngas (mainly composed of carbon monoxide and hydrogen) via the Fischer-Tropsch process, is widely used in modern industry due to its stable physical and chemical properties. As research into molecular structure optimization deepens, the performance of F-T wax has significantly improved, especially in the production and application of adhesives, coatings, and plastics.

The molecular structure optimization of F-T wax primarily involves adjusting chain length, distribution, and branching structure to fine-tune critical physical properties such as melting point, viscosity, and molecular weight distribution. These adjustments greatly enhance the wax's applicability, making it more competitive in various industrial applications.

Traditional F-T waxes typically have relatively uniform structures, often with long linear chains or few branched structures. However, with structural optimization, improvements in molecular weight, melting point, and flow properties have been achieved. This new optimized structure not only boosts thermal and chemical stability but also enhances compatibility with other materials, delivering superior performance across different environments.

In the adhesives industry, F-T wax primarily acts as a tackifier and modifier, improving adhesion, toughness, and heat resistance. After molecular structure optimization, the chain length and distribution of F-T wax are precisely controlled, resulting in better flowability and adhesion. Optimized F-T wax exhibits higher temperature stability and stronger adhesion, especially in high-performance hot melt adhesives, packaging glues, and industrial adhesives, where it maintains excellent performance even in high-temperature or harsh environments.

For example, King Honor, a company with extensive experience in the wax product sector, provides F-T wax products widely used in various adhesives. Their optimized F-T wax not only enhances adhesive stability and lifespan but also improves performance on high-speed production lines, particularly excelling in bonding technology for electronic product packaging and the automotive industry.

The coatings industry demands increasingly high standards for raw materials, particularly concerning environmental protection and performance. Optimized F-T wax, with its low volatility, excellent heat resistance, and outstanding oxidation resistance, has become a vital component in coatings. This optimization enhances gloss and wear resistance while improving coating smoothness and leveling. These features make optimized F-T wax especially suitable for high-performance and eco-friendly coatings, boosting application convenience and long-term stability.

F-T wax also contributes to coatings by acting as a thickener and anti-settling agent. Structural optimization enables the wax to disperse more effectively in the coating matrix, reducing sedimentation during storage and transportation while enhancing chemical resistance and anti-pollution properties. King Honor’s high-performance F-T wax has become a preferred raw material for numerous coating manufacturers due to its excellent properties and compatibility.

In the plastics industry, F-T wax functions as a modifier and plasticizer, improving processability and physical properties. Molecular structure optimization results in more uniform chain lengths and significantly enhanced flowability and stability, making F-T wax widely applicable in modifying various plastics like polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). Optimized F-T wax effectively enhances surface lubrication, reduces friction coefficients, and improves molding properties and aging resistance.

Moreover, optimized F-T wax provides additional protection for plastics against oxidation, UV degradation, and heat, extending the lifespan of plastic products. Given the growing domestic and international demand for high-performance plastics, optimized F-T wax has become an essential raw material for many high-end plastic manufacturers.

As molecular structure optimization technology for F-T wax continues to advance, its applications in adhesives, coatings, and plastics industries are poised for significant growth. For companies like King Honor, optimized F-T wax not only elevates product quality and market competitiveness but also offers more stable and efficient solutions for clients in China and worldwide. With ongoing technological progress, we can expect even broader applications of F-T wax, driving product performance improvements and injecting new vitality into industrial development.

Want to explore how optimized F-T wax can enhance your products and drive business growth? Contact us today—King Honor is ready to provide expert guidance and tailored solutions to meet your needs.

Products:KHWAX QP115H, KHWAX QP105HN, KH FT WAX 85.