Search

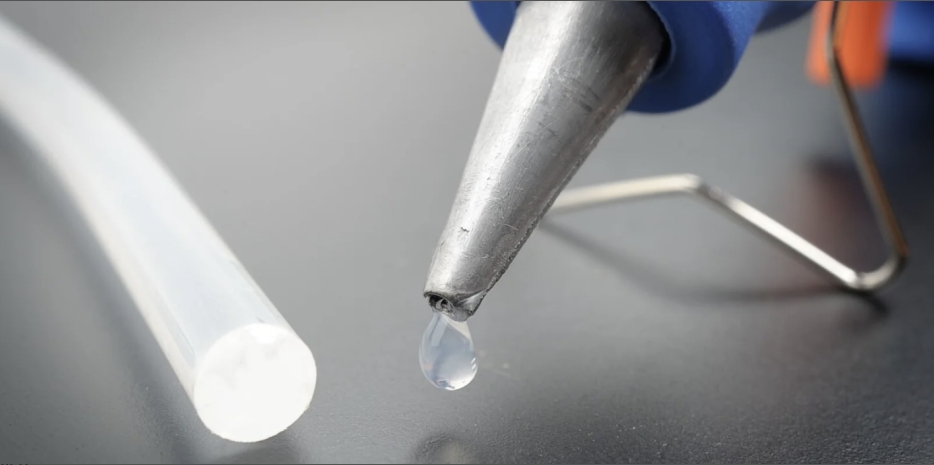

In the production and application of hot melt adhesives, both excessively high and low viscosities can lead to the following problems:

1.1 Increased Difficulty in Operation: High viscosity can affect the flowability of the adhesive, leading to uneven coating.

1.2 Reduced Bonding Performance: Low viscosity may result in insufficient bonding strength, impacting product quality.

1.3 Lower Production Efficiency: Unsatisfactory viscosity can extend processing time and increase energy consumption.

The fischer tropsch wax, with its high melting point, narrow molecular weight distribution, and good lubricity, offers significant advantages in adjusting the viscosity of hot melt adhesives:

2.1 Reducing Viscosity and Improving Flowability

Fischer-Tropsch wax can lower the overall viscosity of hot melt adhesives, enhancing their flowability at high temperatures, making it easier to apply a uniform coating.

It is particularly suitable for applications that require thin-layer coatings, such as packaging materials and label adhesion.

2.2 Enhancing Colloidal Structure Stability

Fischer-Tropsch wax has a high crystallinity, which improves the internal structure of the adhesive, allowing it to maintain stable viscosity across varying temperatures.

This helps to reduce viscosity fluctuations during storage or use, increasing reliability.

2.3 Improving Heat Resistance and Peel Strength

The high melting point of Fischer-Tropsch wax enhances the heat resistance of hot melt adhesives, preventing issues like sagging in high-temperature environments.

It improves the peel strength of the adhesive layer, strengthening bonding performance, especially in industrial applications that require strong adhesion.

2.4 Improving Mold Release Properties

In applications requiring mold release, Fischer-Tropsch wax reduces adhesive adhesion to molds, improving production efficiency.

It is ideal for high-precision fields, such as electronics packaging.

3.1 Control of Usage Amount

The addition of Fischer-Tropsch wax is typically controlled between 1-5%, depending on the specific hot melt adhesive formulation, to achieve optimal viscosity adjustment.

3.2 Compatibility with Other Ingredients

Ensure that synthetic paraffin wax is compatible with the main components of the hot melt adhesive (such as EVA, polyethylene, etc.) to avoid issues like stratification or precipitation.

3.3 Selecting the Right Type

Choose Fischer-Tropsch Synthetic Wax with appropriate melting points and molecular weight based on the specific application of the hot melt adhesive (e.g., packaging, edge banding for wood, automotive interiors) to achieve the best performance.

Packaging Industry: A customer experienced high viscosity in their hot melt adhesive, leading to uneven coating. By adding 2% FT wax china, the flowability was significantly improved, resulting in better coating efficiency and maintaining bonding strength.

Furniture Manufacturing: In wood edge banding, Fischer-Tropsch wax from leading was used to optimize the flowability of the hot melt adhesive while enhancing its heat resistance, solving the issue of adhesive failure in high-temperature environments.

Fischer-Tropsch wax has a significant effect on adjusting the viscosity of hot melt adhesives. It not only improves flowability and operational performance but also enhances bonding strength and heat resistance. By carefully selecting and using Fischer-Tropsch wax, the overall performance and production efficiency of hot melt adhesives can be greatly enhanced.

If you’re ready to enhance the performance, efficiency, and reliability of your hot melt adhesives, we’re here to help. Contact us today to learn more about how Fischer-Tropsch wax can revolutionize your formulations.