Search

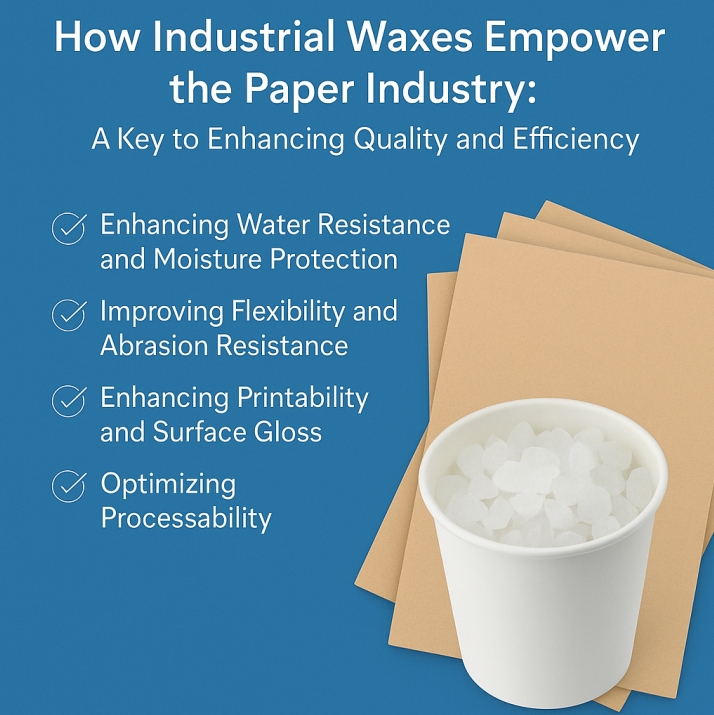

In the paper industry, the diverse performance requirements for packaging, printing, waterproofing, and more have rendered single raw materials and traditional processes insufficient to meet the growing demand for high-quality paper products. Industrial wax—especially premium-grade paraffin wax and Fischer-Tropsch (FT) wax—is becoming an essential material driving the industry's transformation. As a leading industrial wax supplier in China, King Honor (KH) offers a professional product line and technical support, providing efficient and reliable solutions to customers in the paper industry.

1. Enhanced Water and Moisture Resistance

Applying paraffin wax or wax emulsions to the paper surface significantly improves water resistance. This is widely used in food wrapping paper, cupstock, PE-coated paper, and other products requiring strong vapor barriers.

2. Improved Flexibility and Abrasion Resistance

Adding microcrystalline wax or FT wax can enhance the paper’s toughness, preventing cracks during folding or printing, and also improve the feel and durability of the finished product—ideal for premium packaging boxes and book covers.

3. Better Printability and Surface Gloss

By optimizing the type and proportion of wax used, industrial wax can adjust the surface tension of the paper to ensure more even ink adhesion, clearer printed images, and a more attractive finish.

4. Improved Processing Performance

In applications such as heat-sealable paper or thermal paper, high-melting-point paraffin or FT wax ensures material stability during high-speed production, improving processing efficiency and reducing waste.

KH offers a comprehensive range of industrial wax products, including high-, medium-, and low-melting-point paraffin waxes, FT waxes, microcrystalline waxes, and wax emulsions, catering to the diverse needs of the paper industry. KH's product advantages include:

1.Wide Melting Point Range (48°C to 74°C): Suitable for various processes and applications.

2.High Purity and Gloss: Ensures stable paper performance and an attractive appearance.

3.Reliable Supply Capacity: Efficient logistics system ensures timely delivery.

KH’s industrial wax products are widely used in:

1.Packging paper (food-grade and industrial)

2.Greaseproof and waterproof paper

3.Heat-sealable and laminated paper

4.Water-based coated paper

5.Eco-friendly disposable products such as paper cups, bowls, and trays

Additionally, KH provides customized product solutions for paper manufacturers. Based on different paper substrates and performance requirements, KH can tailor wax formulations by adjusting key parameters such as melting point, hardness, and fluidity.

For more information on product details and technical support, please contact us.